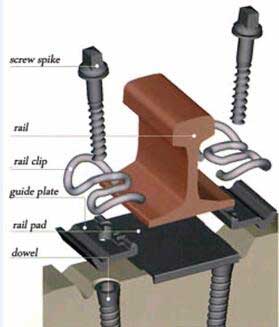

Railway plastic dowel is also called railway ferrule, railroad plastic sleeve, rail plastic insert, concrete insert or rail dowel for concrete sleeper. It is usually imbedded into the concrete sleeper together with railroad screw spikes to guide railroad tie plates and rail clips to fasten the rail track.

Railway plastic dowel is usually used in the rail fastening system as foundation. It is inserted into the concrete sleeper separately before assembling other fastening accessories to form rail fastening system. Rail plastic sleeve ensures the good connection and linkage of rail fastening system with concrete sleeper, screw spikes or rail track bolts.

Moreover, another function of rail plastic dowel insert is to insulate the railroad fasteners from the ties. Therefore, the strength and fatigue life of the rail plastic sleeve is crucial to the safety of the whole rail track line. Taking WJ-8 fastening system for example, the collaboration of anchor bolts and imbedded plastic sleeves in the track slabs make the tie plate tightly fastened to steel rail and railway sleepers. The screw spikes go through rail clips into the railway plastic dowel, to fulfill a enough elasticity range, to avoid the rail bolt against becoming loose, and to decrease the maintenance work accordingly.

Rail plastic dowel is usually used in SKL fastening systems, and can be classified according to its raw materials: PA66 or HDPE, depending on different technical specification requirements of clients.

Types of Railway Plastic Dowel

| Type | For different sizes of screw spikes or anchor bolts | |

|---|---|---|

| Material | Reinforced Nylon 66 (PA66: Nylon 66.69%, glass fiber 30%, other 1%) | HDPE |

| Technical specifications |

Density:1.3-1.45g/cm3 Tensile strength: ≥170Mpa Elongation: ≤4.4% Bending Strength: ≥250Mpa Impact Strength(No gap): ≥80KJ/m2 Melting point:250-270°C Insulation resistance:≥1×108Ω Glass fiber content:30-35% Hardness:≥110HRR |

Density: 0.95-0.98g/cm3 Tensile strength: ≥19Mpa Elongation: >80% Melting point: 170-190°C Insulation resistance: ≥1×1010Ω Hardness:≥98A |

| Color | Yellow, black, white, blue, green, etc, based on clients' requirements | |

HDPE Rail Sleeve

| Technical Parameter | Density | Tensile Strength | Elongation | Melting Point | Insulation Resistance | Hardness |

|---|---|---|---|---|---|---|

| Unit | g/cm3 | Mpa | % | ℃ | Ω | A |

| Technical Requirement | 0.95-0.98 | ≥19 | >80 | 170-190 | ≥1×1010 | ≥98 |

| Value | 0.95 | 19 | 150 | 190 | 3.5 ×1010 | 98(A) |

PA66 Rail Plastic Dowel (PA66: Nylon 66.69%, Glass Fiber 30%, Other 1%)

| Technical Parameter | Unit | Technical Requirement | Value |

|---|---|---|---|

| Density | g/cm3 | 1.3-1.45 | 1.45 |

| Tensile Strength | Mpa | ≥170 | 178 |

| Elongation | % | ≤4.4 | 4.0 |

| Bending Strength | Mpa | ≥250 | 290 |

| Impact Strength (No gap) | KJ/m2 | ≥80 | 85 |

| Melting Point | ℃ | 250 -270 | 270 |

| Insulation Resistance | Ω | ≥1×108 | 5×108 |

| Glass Fiber Content | % | 30-35 | 35 |

| Hardness | HRR | ≥110 | 118 |

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!